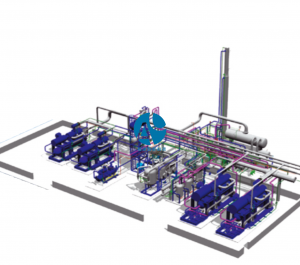

PSA富CO2气流介质二氧化碳回收装置

富CO2气流介质(PSA气体)来源于有代表性质的各种合成气生成过程中常见的reine-ries和石油化工厂的复合物,是一种新型的替代生产食品级二氧化碳的方式。

通过创新,同时结合传统的提取和液化技术,新的CO2生产过程(专利申请中)消除了汽提同时保持能耗在较好的低水平,从而降低食品级CO2从富液分离的生产消耗成本。

CO2从下游PSA回收,消除与SMR生产过程的干扰,使得它适合在现有的和新的SMR厂实施。

从PSA尾气废气中提取CO2后,尾气可以返回到SMR生产作为原料,或作为进一步处理从而能够净化废气,从而提供现有的SMR生产瓶颈的解决方案。

本设备完全自动化,配备先进的自动化技术,可实现远程操作,保证连续、安全运行。

标准设备生产能力范围从1-25吨/小时。要求生产能力根据要求另行提供。

Medium rich CO2 streams (PSA off-gas) generated from various syn-gas processes typically found in reine-ries and petrochemical complexes, is a new alternative for production of food grade CO2.

Utilising an innovative process, combining conventional extraction and liquefaction technologies, the new Flash CO2 process ( patent pending) eliminates the requirement for steam-stripping while still keeping power consumption at attractive levels, subsequently reducing the high production cost usually associated with extraction of food grade CO2 from medium rich sources.

CO2 is recovered downstream the PSA, eliminating any interference with the SMR process, making it suitable for implementation in both existing and new SMR plants.

After extracting CO2 from the PSA off-gas, the off-gas can be returned to the SMR plant and used as fuel, or further treatment can be introduced to purify the waste gases, thereby providing a solution for de-bottle-necking of existing SMR plants.

The plant is fully automated, equipped with advanced automation technology, which enables remote operation and guarantees continuous and safe operation 。

Standard plant capacities range from 1- 25 Tons/hour. Other capacities available on request.