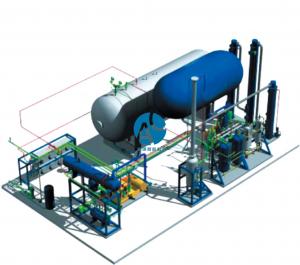

啤酒厂发酵气二氧化碳回收装置

酒精CO2回收设备(RBU)是酿酒发酵通过若干化学过程富集的CO2。

CO2回收设备通过适当清洗、洗涤,过滤与分离技术达到高质量的CO2。

CO2生产设备配有控制面板,确保无故障运行。所有的仪器仪表安装在壳块内,便于运输,减少现场安装、调试时间。

酿酒CO2生产设备生产能力:145公斤/小时,285公斤/小时,500公斤/小时,1000公斤/小时——其它生产能力根据要求另行提供。

在酒精发酵过程释放的CO2气体中含有大量的杂质,首先通过除沫器进行清除泡沫,除沫器之后是三道洗涤器。

原料气经过洗涤器后CO2气体中的酒精和气溶胶被去除,水被输送到除沫器循环利用。CO2气体通过高锰酸钾洗涤器去除NOx,紧接着又一次洗涤,余下的杂质通过水去除。

CO2 Recovery Plants (RBU) are based on recovery from alcohol distillery.CO2 can be recovered from distillery fermenting processes as well as from a number of chemical processes with emission of CO2-rich gases.

Through appropriate washing, scrubbing, filtration and separation technology the CO2 Recovery Plants for distillery process meet the strictest CO2 quality requirements.

The plant is supplied with a control panel which ensures continuous trouble free operation of the plant. All instruments installed on the skids are wired to junction boxes prior to shipment and thus reducing installa-tion and commissioning time on site.

CO2 Recovery Plant for Distillery Process Standard Sizes:

145 kg/hr, 285 kg/hr, 500 kg/hr and 1000 kg/hr other sizes available on requesment

The CO2 gas developed in the distillery fermentation process contains a lot of impurities. First step is to let the CO2 pass a foam trap where it is cleaned for foam. The foam trap is followed by 3 scrubbers.

Raw gas scrubber where the CO2 gas is cleaned for alcohols and aerosoles by means of water, which is reused in the foam trap. The CO2 steams into a permanganate scrubber for removal of NOx, followed by an after scrubber, where the remaining main impurities are removed by means of water.